The Cessna 172 Parts Manual is a comprehensive guide detailing components, maintenance requirements, and replacement procedures for the iconic Cessna 172 aircraft, ensuring safe and efficient operations.

1.1 Overview of the Cessna 172 Aircraft

The Cessna 172, affectionately known as the Skyhawk, is a single-engine, four-seat aircraft renowned for its reliability, durability, and ease of handling. With over 43,000 units produced, it remains the most manufactured airplane in history; Its Lycoming O-320-H2AD engine, fixed-pitch propeller, and robust design make it a favorite for flight training and personal use, ensuring safe and efficient operations for pilots worldwide since its 1956 debut.

1.2 Importance of the Parts Manual for Maintenance and Repair

The Cessna 172 Parts Manual is indispensable for ensuring the aircraft’s airworthiness and longevity. It provides detailed part identification, maintenance schedules, and repair procedures, enabling technicians to address issues efficiently. Compliance with Airworthiness Directives (ADs) and routine inspections relies heavily on this manual. Proper use ensures safety, reduces downtime, and prevents costly repairs by identifying worn or faulty components early, making it a critical resource for owners and mechanics alike.

Airframe Parts and Components

The Cessna 172 airframe consists of the fuselage, wings, and control surfaces, ensuring structural integrity and flight performance. Regular inspections of these components are essential for safety and durability.

2.1 Fuselage and Wing Components

The Cessna 172’s fuselage is constructed from durable aluminum alloys, providing a robust structure for the cockpit and cabin. The wings are designed for efficient lift, with a high-wing configuration reducing drag and enhancing stability during flight. Key components include the wing spars, ribs, and skin panels, all carefully engineered to withstand various flight conditions and ensure optimal performance. Regular inspections of these parts are crucial for maintaining airworthiness and safety.

2.2 Control Surfaces (Ailerons, Elevators, Rudder)

The Cessna 172’s control surfaces, including ailerons, elevators, and rudder, are essential for precise flight control. Ailerons on the wings manage roll, while elevators on the tail control pitch, and the rudder directs yaw. Constructed from aluminum and steel, these surfaces are designed for durability and responsiveness. Regular inspections ensure proper functionality, addressing issues like wear or misalignment. Lubrication of hinges and linkages is critical for smooth operation and safety.

2.3 Landing Gear and Brakes

The Cessna 172 features a fixed tricycle landing gear, providing stability during takeoff, landing, and taxiing. Constructed from durable steel, the gear withstands various flight conditions. Hydraulic brakes, actuated by toe pedals, ensure reliable stopping power. Regular inspections of brake pads, rotors, and hydraulic lines are crucial for safe operation. Lubrication of gear hinges and inspection for wear or corrosion are recommended to maintain optimal functionality and prevent potential issues during ground operations.

Engine and Fuel System Parts

The Cessna 172 is powered by the Lycoming O-320-H2AD engine, a reliable four-cylinder, air-cooled powerplant. The fuel system includes tanks, pumps, and lines, ensuring efficient fuel delivery for optimal performance.

3.1 Lycoming O-320-H2AD Engine Overview

The Lycoming O-320-H2AD engine powers the Cessna 172, offering a reliable 160 horsepower. Known for its durability and efficiency, this air-cooled, four-cylinder engine features a direct-drive propeller system. Regular maintenance is crucial, with specific attention to oil changes, spark plugs, and cylinder compression checks. Proper care ensures optimal performance and longevity, making it a cornerstone of the aircraft’s dependability.

3.2 Fuel System Components (Tanks, Pumps, Lines)

The Cessna 172 fuel system includes two wing-mounted aluminum tanks, each holding approximately 26 gallons. The system features mechanical and electric fuel pumps, with the latter serving as a backup. Fuel lines connect the tanks to the engine, ensuring proper flow. The fuel strainer filters debris, while the selector valve allows switching between tanks. Regular inspection of these components is essential for safe operation and compliance with airworthiness directives.

Avionics and Electrical System Parts

The Cessna 172 features standard avionics, including radios, GPS, and flight instruments, alongside an electrical system with batteries, alternators, and circuit breakers, ensuring reliable aircraft operations.

4.1 Standard Avionics Equipment (Radios, GPS, Instruments)

The Cessna 172 is equipped with essential avionics, including VHF radios for communication, GPS navigation systems, and flight instruments such as altimeters, airspeed indicators, and heading indicators. These systems provide critical data for safe flight operations, aiding pilots in navigation, altitude control, and situational awareness. Upgraded models may feature advanced glass cockpit setups, enhancing functionality and ease of use for pilots.

4.2 Electrical System Components (Batteries, Alternators, Circuit Breakers)

The Cessna 172’s electrical system includes a battery for power storage, an alternator for charging, and circuit breakers for overload protection. Regular inspections ensure reliability, with battery lifespan typically ranging from 5 to 7 years. Circuit breakers should be checked for proper function, and alternators maintained to prevent voltage fluctuations. Proper maintenance of these components is vital for consistent electrical system performance and safety during flight operations.

Flight Control and Trim System Parts

The Cessna 172’s flight control system includes primary controls such as the yoke, pedals, and trim wheel. These components ensure precise aircraft maneuverability and stability during flight.

5.1 Primary Flight Controls (Yoke, Pedals, Trim Wheel)

The primary flight controls of the Cessna 172 include the control yoke, rudder pedals, and trim wheel. These components are essential for precise aircraft maneuverability. The control yoke controls roll and pitch, while the rudder pedals manage yaw and directional control. The trim wheel adjusts aerodynamic forces, ensuring smooth and efficient flight operations. Proper maintenance is crucial for optimal performance and safety.

5.2 Trim System Components (Trim Motors, Actuators)

The trim system in the Cessna 172 consists of motors and actuators that regulate the aircraft’s trim settings. These components adjust the control surfaces to maintain steady flight, reducing pilot workload. Motors drive the trim mechanisms, while actuators convert electrical signals into mechanical movements. Regular inspection and maintenance of these parts ensure precise control and smooth operation during all phases of flight, enhancing overall aircraft performance and safety.

Interior and Safety Components

The Cessna 172’s interior includes seats, panels, and carpets, while safety components comprise seat belts, fire extinguishers, and emergency locator transmitters, ensuring passenger and pilot safety.

6.1 Cabin Interior Parts (Seats, Panels, Carpets)

The Cessna 172’s cabin interior includes durable seats, lightweight panels, and sound-absorbing carpets. These components enhance comfort and aesthetics while maintaining functionality. Regular inspection of seats and panels ensures safety, while carpets reduce noise levels during flight, contributing to a more pleasant flying experience for passengers and pilots alike.

6.2 Safety Equipment (Seat Belts, Fire Extinguisher, Emergency Locator Transmitter)

The Cessna 172 is equipped with essential safety equipment, including seat belts, a fire extinguisher, and an Emergency Locator Transmitter (ELT). These components ensure pilot and passenger safety in critical situations. Regular inspection and maintenance of these items are crucial to guarantee their functionality and compliance with aviation regulations, thereby enhancing overall flight safety and preparedness for emergencies.

Maintenance and Inspection Guidelines

Regular maintenance and inspections are vital for ensuring the Cessna 172’s airworthiness. Annual inspections, compliance with ADs, and prompt addressing of wear and tear are essential.

7.1 Annual Inspection Requirements

The annual inspection is a detailed evaluation of the Cessna 172’s airworthiness, requiring 17-20 man-hours. It includes checking engine performance, fuel system integrity, and airframe condition. Compliance with Airworthiness Directives (ADs) is mandatory. Inspectors review maintenance logs, test systems, and inspect for wear and tear. Any discrepancies must be addressed to ensure safety and regulatory compliance. This thorough process ensures the aircraft remains operational and safe for flight.

7.2 Common Wear and Tear Parts to Inspect

The Cessna 172’s parts manual highlights key components prone to wear and tear. Landing gear, control surfaces, and engine mounts often show signs of fatigue. Fuel pumps, lines, and electrical connectors may develop leaks or corrosion. Regular inspections of these parts are crucial to prevent major issues. Early detection of cracks or excessive wear ensures safety and reduces maintenance costs.

Troubleshooting Common Issues

Identify and address common issues like flap vibrations, engine performance problems, and electrical malfunctions using diagnostic tools and maintenance best practices outlined in the manual.

8.1 Flap and Aileron Vibrations

Flap and aileron vibrations in the Cessna 172 can occur due to worn hinges, misaligned components, or improper flap extension speeds. Symptoms include shaking during flap deployment and vibrational forces felt through the aircraft. Inspect hinge pins, flap tracks, and aileron bearings for wear or looseness. Lubricate moving parts and ensure proper alignment. Addressing these issues promptly prevents further damage and maintains smooth flight operations, as outlined in the parts manual.

8.2 Engine Performance Problems

Engine performance issues in the Cessna 172, such as rough running or loss of power, often stem from faulty fuel injection systems, clogged air filters, or ignition system malfunctions. Low compression, excessive oil consumption, or worn piston rings may also contribute. Regular inspection of spark plugs, fuel lines, and engine mounts is crucial. Referencing the parts manual ensures proper diagnostics and repair, maintaining optimal engine efficiency and safety during flight operations.

Compliance with Airworthiness Directives (ADs)

ADs are mandatory regulations ensuring aircraft safety and compliance with federal aviation standards. Tracking AD compliance for critical Cessna 172 parts is essential for maintaining airworthiness and operational integrity.

9.1 Understanding AD Requirements for the Cessna 172

Airworthiness Directives (ADs) are regulatory requirements issued by aviation authorities to address specific safety concerns. For the Cessna 172, ADs often target critical components like engines, wings, and control surfaces. Compliance ensures the aircraft meets safety standards, preventing potential failures. ADs may mandate inspections, modifications, or part replacements. Understanding and adhering to these directives is crucial for maintaining the aircraft’s airworthiness and operational safety.

9.2 Tracking AD Compliance for Critical Parts

Tracking AD compliance for critical Cessna 172 parts involves documenting inspections, repairs, and replacements. Maintaining detailed records ensures adherence to safety regulations. Digital tools and logbooks are essential for monitoring compliance. Regular audits help verify that all AD requirements are met, preventing potential penalties and ensuring continued airworthiness. Proper tracking also aids in planning maintenance schedules and budgeting for necessary upgrades or replacements, ensuring the aircraft remains safe and operational.

Resources and References

Key resources include official Cessna 172 manuals, online forums, and tool recommendations for maintenance and repair, ensuring access to reliable information and support for aircraft upkeep.

- Official Cessna 172 Parts Manuals and Documentation

- Online Forums and Communities for Parts Discussions

- Recommended Tools for Maintenance and Repair

10.1 Official Cessna 172 Parts Manuals and Documentation

The official Cessna 172 parts manual provides detailed schematics, part numbers, and maintenance instructions. It is available on the Cessna website and FAA resources. Key sections include the parts catalog, maintenance procedures, and compliance guidelines. The manual ensures accurate repairs and adherence to safety standards. Additional documentation, such as the Pilot’s Operating Handbook (POH), offers operational insights. These resources are essential for mechanics and pilots to maintain airworthiness and performance.

- Parts Catalog with Detailed Schematics

- Maintenance and Inspection Procedures

- Compliance and Airworthiness Guidelines

- Supplemental Documentation (POH, Service Bulletins)

10.2 Online Forums and Communities for Parts Discussions

Online forums and communities provide valuable resources for discussing Cessna 172 parts and maintenance. Platforms like the Cessna Pilots Association and AOPA forums offer peer support, troubleshooting tips, and shared experiences. Websites like Reddit’s r/aviation and specialized aviation groups allow pilots and mechanics to exchange insights. These communities often discuss specific parts, such as flap mechanisms or engine components, and share solutions for common issues, fostering a collaborative environment for aircraft maintenance and upgrades.

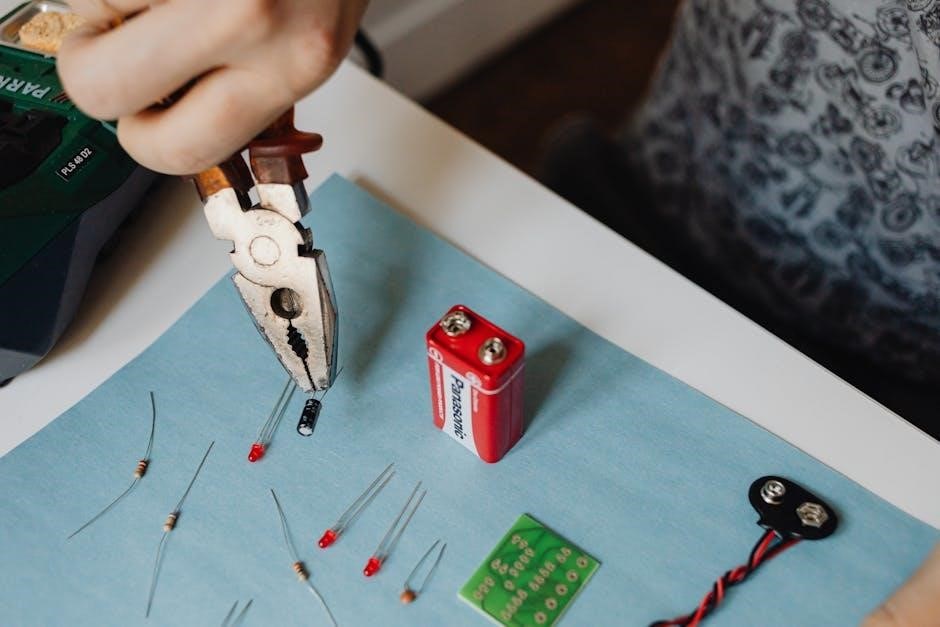

10.3 Recommended Tools for Maintenance and Repair

Essential tools for maintaining the Cessna 172 include torque wrenches, rivet guns, and multimeters. A precision torque wrench ensures proper bolt tightening, while a rivet gun is vital for structural repairs. A multimeter aids in diagnosing electrical issues. Additional tools like wire strippers and socket sets are indispensable. For detailed work, aircraft-specific toolkits and diagnostic software are recommended to streamline maintenance and ensure compliance with airworthiness standards.

The Cessna 172 Parts Manual is an essential resource for maintaining and repairing the aircraft, ensuring safety, efficiency, and compliance with airworthiness standards.

11.1 Summarizing Key Components of the Parts Manual

The Cessna 172 Parts Manual outlines essential components for maintenance, including airframe structures, engine parts, avionics, and flight controls. It covers fuselage, wings, landing gear, and electrical systems, ensuring clarity for repairs. The manual also details safety equipment and interior components, providing a comprehensive reference for technicians. Understanding these parts is crucial for maintaining airworthiness and ensuring safe, efficient aircraft operation.

11.2 Final Tips for Effective Use of the Manual

Always cross-reference parts with diagrams for accuracy and attend maintenance workshops for hands-on experience. Regularly update your manual to reflect the latest ADs and service bulletins. Use online forums for troubleshooting and share insights with other technicians. Prioritize routine inspections and document all repairs for future reference. Leveraging digital tools can enhance navigation and streamline maintenance tasks, ensuring compliance and safety standards are consistently met.