General Description of the Dixell Universal Controller

The Dixell Universal Controller is a microprocessor-based device designed for refrigeration systems, offering versatility and ease of use. Its compact 71×29 mm format ensures compatibility with various applications, including high, medium, and low-temperature units. With multiple voltage options, it supports 12/24Vac/dc, 120Vac, and 230Vac, making it adaptable to different electrical systems. The controller features three relay outputs for compressor, defrost (electrical or hot gas), and evaporator fan control, ensuring efficient system management. Its user-friendly design simplifies installation and operation, making it a reliable choice for refrigeration technicians and professionals.

1.1. Key Features and Benefits

The Dixell Universal Controller offers multiple voltage options (12/24Vac/dc, 120Vac, 230Vac) for flexibility across applications. Its compact 71×29 mm design ensures easy installation in various refrigeration systems. Three relay outputs control compressors, defrost (electrical or hot gas), and evaporator fans, optimizing system performance. User-friendly programming and adaptable settings make it ideal for technicians, ensuring efficient and reliable operation in high, medium, or low-temperature environments.

1.2. Design and Compatibility

The Dixell Universal Controller measures 71×29 mm, ensuring a compact and space-efficient design. It supports multiple voltage options, including 12/24Vac/dc, 120Vac, and 230Vac, enhancing its compatibility across various electrical systems. Designed for high, medium, and low-temperature refrigeration units, this controller offers versatile integration capabilities, making it suitable for diverse applications in the refrigeration industry.

Installation and Operating Instructions

The Dixell Universal Controller’s installation and operating instructions are detailed in its manual, available in PDF format. It guides users through setup, configuration, and operation steps.

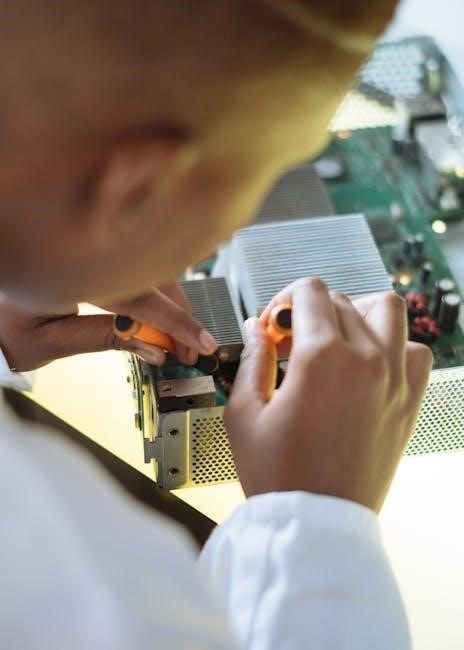

2.1. Step-by-Step Installation Guide

The installation begins with selecting the appropriate controller model for your system. Mount the controller securely, ensuring proper ventilation. Connect power supply and input/output terminals according to the wiring diagram. Configure the controller settings using the keypad or programming tool. Test all functions, including compressor, defrost, and fan operations. Refer to the manual for specific model instructions and safety precautions to ensure a trouble-free setup.

2.2. Operating Parameters and Settings

The Dixell Universal Controller operates within a wide temperature range, supporting high, medium, and low-temperature applications. It offers adjustable defrost cycles, including electrical and hot gas options, to suit different systems. Users can configure settings for compressor operation, evaporator fan control, and temperature setpoints. The controller also allows customization of defrost intervals, durations, and temperatures to optimize performance. Refer to the manual for detailed parameter adjustments and operational limits to ensure efficient and safe system operation.

Technical Specifications

The Dixell Universal Controller features a compact 71×29 mm design, supporting 12/24Vac/dc, 120Vac, and 230Vac voltages. It includes three relay outputs for compressor, defrost, and fan control, ensuring compatibility with various refrigeration systems. The controller operates across high, medium, and low-temperature applications, making it versatile for different environmental demands.

3.1. Voltage Options and Compatibility

The Dixell Universal Controller offers flexible voltage options, including 12/24Vac/dc, 120Vac, and 230Vac, ensuring compatibility with diverse electrical systems. Its compact 71×29 mm design accommodates high, medium, and low-temperature refrigeration applications, making it versatile for various environments. The controller’s microprocessor-based technology allows seamless integration across different voltage requirements, enhancing its adaptability in commercial and industrial refrigeration systems worldwide.

3.2. Dimensions and Mounting Requirements

The Dixell Universal Controller measures 71×29 mm, designed for compact installations. Its slim profile ensures easy mounting on standard DIN rails, saving space in control panels. The controller’s durable construction withstands typical environmental conditions, and its lightweight design simplifies handling during installation. Mounting requirements are minimal, making it a practical solution for various refrigeration systems without compromising performance or reliability.

Relay Outputs and Their Functions

The Dixell Universal Controller features three relay outputs, each serving distinct functions: compressor control, defrost management (electrical or hot gas), and evaporator fan regulation, ensuring precise system operation.

4.1. Compressor Control

The compressor control relay ensures efficient and reliable operation of the refrigeration system. It manages start/stop cycles, preventing excessive wear and optimizing performance. Compatible with various voltage options, it supports high, medium, and low-temperature applications. The controller’s microprocessor ensures precise temperature management, maintaining set points while adapting to system demands. This feature is crucial for energy efficiency and system longevity, ensuring smooth operation across different refrigeration setups.

4.2. Defrost Management (Electrical or Hot Gas)

4.2. Defrost Management (Electancial or Hot Gas)

The Dixell Universal Controller offers advanced defrost management, supporting both electrical and hot gas defrost systems. It provides user-adjustable settings for defrost intervals, duration, and temperature thresholds, ensuring optimal performance. The controller’s microprocessor handles defrost cycles efficiently, preventing excessive ice buildup and maintaining energy efficiency. This feature is essential for maintaining system reliability and extending equipment lifespan in refrigeration applications.

4.3. Evaporator Fan Control

The Dixell Universal Controller includes advanced evaporator fan control, optimizing airflow and system performance. It supports adjustable settings for fan operation, ensuring efficient temperature management. The controller’s microprocessor-based system allows for precise control, reducing energy consumption and maintaining optimal conditions. This feature is particularly beneficial in medium and low-temperature applications, enhancing overall system reliability and performance.

Defrost Management Capabilities

The Dixell Universal Controller offers advanced defrost management with customizable cycles for electrical or hot gas systems, enhancing efficiency and system performance in refrigeration applications.

5.1. Types of Defrost Cycles

The Dixell Universal Controller supports multiple defrost cycles, including electrical, hot gas, and adaptive defrost modes. These cycles are designed to optimize efficiency and prevent excessive ice buildup. Electrical defrost uses heaters, while hot gas defrost utilizes refrigerant to melt ice. Adaptive cycles adjust based on system conditions, ensuring minimal downtime and energy savings. Users can customize defrost intervals and durations to suit specific applications, enhancing overall system performance and reliability.

5.2. User-Adjustable Defrost Settings

The Dixell Universal Controller allows users to customize defrost settings, including cycle frequency, duration, and temperature thresholds. These adjustments optimize system performance and energy efficiency. The intuitive interface enables easy configuration, ensuring tailored operation for various refrigeration applications. This flexibility supports efficient defrost management, minimizing downtime and enhancing overall system reliability.

Troubleshooting and Maintenance

This section provides solutions for common issues and maintenance tips to ensure optimal performance. Users can identify and resolve problems efficiently using diagnostic features and guidelines.

6.1. Common Issues and Solutions

Common issues include sensor malfunctions, incorrect voltage supply, and relay failures. Solutions involve checking connections, ensuring proper voltage, and replacing faulty components. Error codes provide diagnostic clues, guiding users to specific problems. Regular maintenance, such as cleaning sensors and updating software, prevents issues. Refer to the manual for detailed troubleshooting steps and solutions to ensure optimal controller performance and longevity.

6.2. Error Codes and Diagnostic Features

The Dixell Universal Controller features error codes to diagnose issues quickly. Codes like E1 and E2 indicate specific problems, such as sensor faults or communication errors. The controller’s diagnostic mode provides detailed insights, allowing users to identify and resolve issues efficiently. Refer to the manual for a full list of codes and their meanings to ensure proper troubleshooting and maintenance, optimizing system performance and reliability.

Additional Features and Upgrades

The Dixell Universal Controller supports software updates and programming via HOT KEY, ensuring enhanced functionality. It integrates seamlessly with other Dixell products, offering advanced monitoring and control capabilities.

7.1. Software Updates and Programming

The Dixell Universal Controller allows for seamless software updates, ensuring optimal performance and new features. Programming is facilitated through the HOT KEY interface, enabling technicians to customize settings and adapt the controller to specific refrigeration needs. Regular updates enhance compatibility and functionality, maintaining peak efficiency across various applications. This feature ensures the controller remains up-to-date with the latest technological advancements in refrigeration control systems.

7;2. Integration with Other Dixell Products

The Dixell Universal Controller seamlessly integrates with other Dixell products, such as the X-WEB monitoring units, enabling advanced system monitoring and control. Compatibility with Dixell’s programming tools, like the HOT KEY interface, allows for centralized management and customization. This integration enhances overall system performance, ensuring efficient operation across all connected devices. It simplifies setup and maintenance, making it ideal for comprehensive refrigeration solutions.

Safety Precautions and Warnings

Avoid exposing the controller to water or moisture. Ensure proper voltage matching before connection. Use the device in dry environments and follow installation guidelines carefully for optimal safety.

8.1. Electrical Safety Guidelines

Always verify the controller’s voltage compatibility with your system before installation. Avoid overloading circuits and ensure proper grounding. Use insulated tools to prevent electric shock. Keep the controller dry and avoid exposing it to water or moisture. Never connect or disconnect wires while the power is on. Follow all local electrical codes and regulations for safe installation and operation.

8.2. Environmental Usage Restrictions

The Dixell Universal Controller is designed for use in controlled environments, avoiding extreme temperatures and humidity. It should not be exposed to outdoor weather conditions or corrosive substances. Ensure the operating environment complies with the manufacturer’s specified temperature and humidity ranges to maintain optimal performance and longevity of the device.

Warranty and Support Information

Dixell offers a comprehensive warranty covering manufacturing defects; For support, contact their team via email or visit their official website for detailed assistance and guidance.

9.1. Warranty Terms and Conditions

Dixell’s warranty covers manufacturing defects for a specified period. The warranty is void if the product is misused or modified. For details, refer to the official manual or contact Dixell support directly. Proper registration and adherence to usage guidelines are essential to maintain warranty validity. Ensure all claims are submitted within the stated timeframe for prompt assistance.

9.2. Contacting Dixell Support

Dixell Support can be contacted directly via email at support@dixell.com or through their official website at www.dixell.com. The website offers extensive resources, including manuals, FAQs, and troubleshooting guides. For assistance with error codes or technical issues, users can reach out to Dixell’s support team, ensuring prompt resolution.

Resources and Downloads

Dixell provides comprehensive resources, including manuals, user guides, and FAQs, accessible via their official website. These resources support installation, operation, and troubleshooting, ensuring optimal performance.

10.1. Accessing the Latest Manuals

Dixell offers free downloads of manuals and user guides for their Universal Controller models, such as XR60CX and XR20C, in PDF format. These documents are accessible via Dixell’s official website, ensuring users have the most up-to-date information. Updated instruction sheets, technical slides, and QR codes for easy access are also available. Visit www.dixell.com or refer to the provided QR codes for additional support materials and resources.

10.2. Online Support and FAQs

Dixell provides comprehensive online support and FAQs to assist users with troubleshooting and understanding their Universal Controllers. The official website features detailed technical documentation, troubleshooting guides, and error code explanations. Users can also access diagnostic tools and software updates for optimal performance. For additional help, Dixell’s customer support team is reachable via email at dixell@dixell.com, ensuring prompt assistance and resolving any controller-related issues efficiently.

Environmental and Regulatory Compliance

Dixell Universal Controllers comply with international environmental standards, ensuring eco-friendly operation and safe disposal. They meet regulatory requirements, minimizing environmental impact while maintaining high performance and reliability across applications.

11.1. Compliance Certifications

Dixell Universal Controllers are certified to meet international standards, including RoHS, CE, and UL, ensuring compliance with environmental and safety regulations. These certifications guarantee the absence of hazardous substances, adherence to EU directives, and safety standards for North American markets, respectively. Dixell products are designed to meet rigorous quality and environmental requirements, ensuring reliability and sustainability in refrigeration applications worldwide.

11.2. Recyclability and Disposal Guidelines

Dixell Universal Controllers are designed with recyclability in mind, featuring components that can be safely reused or disposed of. Proper disposal involves separating electronic components from hazardous materials, adhering to local regulations. Users are encouraged to recycle through certified e-waste facilities to minimize environmental impact. Detailed guidelines are available in Dixell’s environmental compliance documents, ensuring responsible end-of-life management for their products.

The Dixell Universal Controller offers exceptional performance and efficiency. Regular maintenance and adherence to guidelines ensure optimal functionality and longevity of the device.

12.1. Best Practices for Long-Term Use

For optimal performance, ensure regular software updates and proper installation. Protect the controller from environmental stressors like moisture and extreme temperatures. Periodically review settings to align with operational needs. Follow maintenance schedules and refer to the manual for specific guidelines. Consistent monitoring and timely adjustments will enhance reliability and extend the controller’s lifespan, ensuring efficient refrigeration system operation.

12.2. Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the Dixell Universal Controller operates efficiently and reliably. Schedule periodic checks of electrical connections, clean components, and verify settings alignment with system requirements. Addressing potential issues early prevents unexpected downtime. Adhering to maintenance schedules enhances performance, extends lifespan, and ensures optimal refrigeration system control. Proper care safeguards your investment and guarantees consistent operation over time.